Airoptic

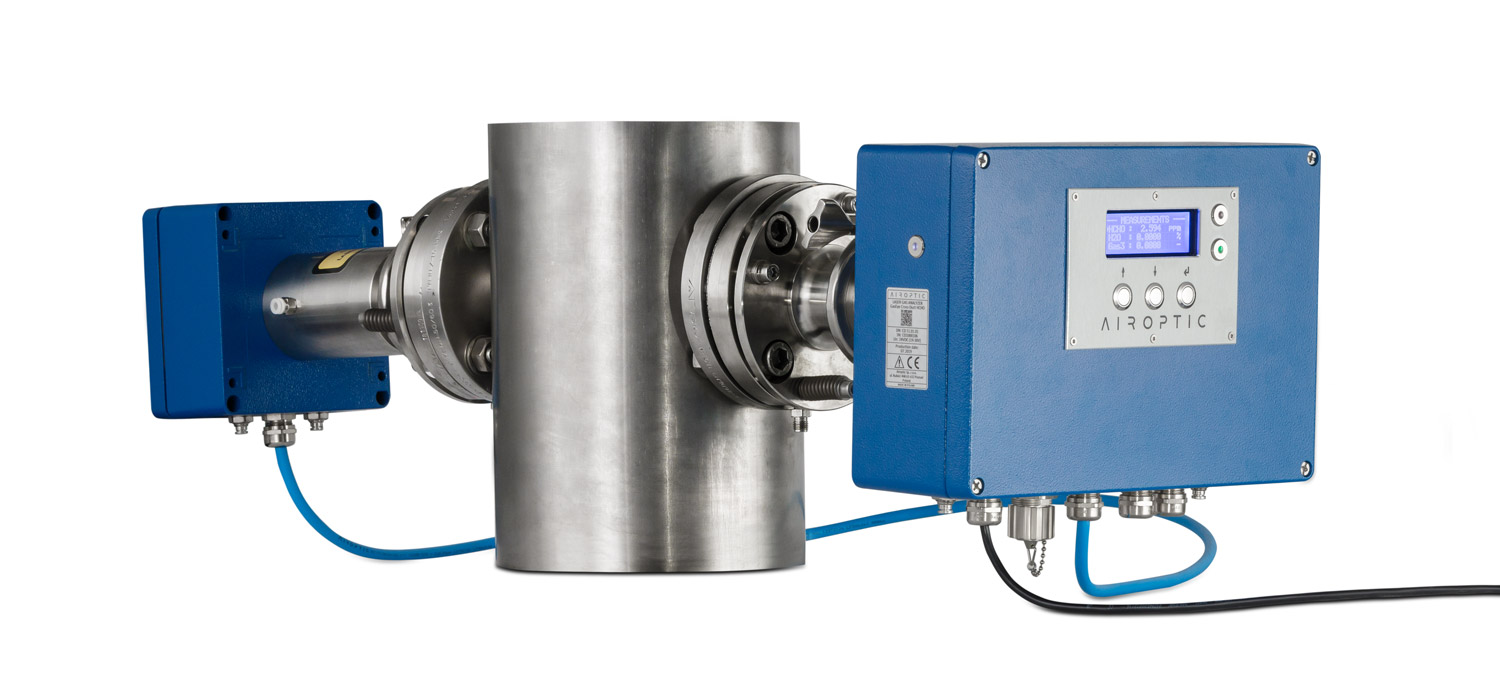

GasEye Cross Duct

GasEye Cross Duct is a single or multi-laser analyzer that utilizes tunable diode laser (TDL) absorption spectroscopy. The central unit sends a laser light through the process which is detected by the receiver unit mounted on the opposite side of the process. When a gas of interest is present in this process, it will absorb the laser light. The optical power detected in the receiver unit will depend on the concentration of the gas, temperature, pressure, and optical pathlength according to Lambert’s Beer law. Thus in order to determine the gas concentration, the analyzer requires information regarding temperature, pressure, and optical pathlength. Temperature and pressure signals can be provided by analog inputs, via industrial communication protocols, or as manual values via Webserver or HMI.

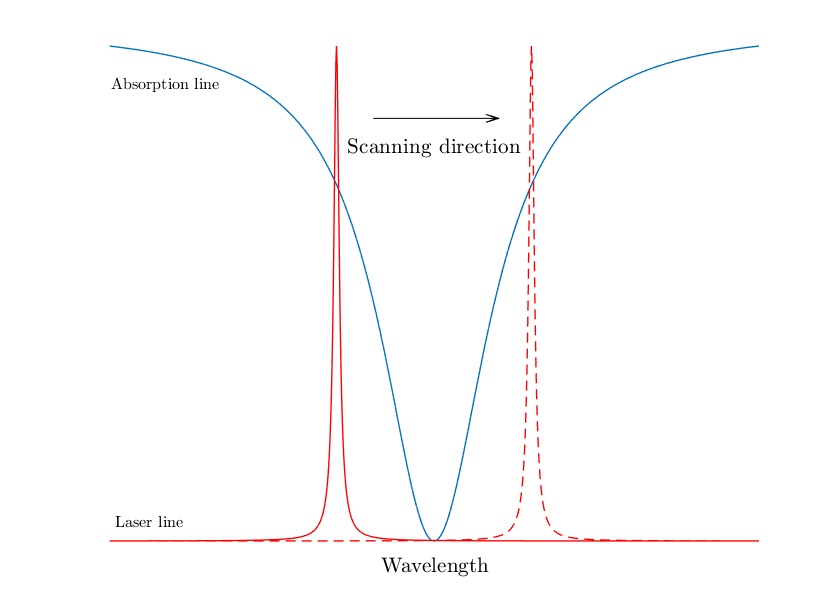

In the GasEye Cross Duct analyzer, the laser wavelength is specifically chosen to match the fingerprint region of the particular gas of interest and is being continuously scanned over the absorption line(s). Since full spectral information is recovered with very high spectral resolution the analyzer remains immune to foreign gas broadening and is immune to cross-interferences from dust and any other gas constituents in the process. GasEye Cross Duct by design can operate in several wavelength regions from Near-Infrared to Mid-Infrared.

Example Applications

- Combustion control

- Safety monitoring

- Electrofilter Protection

Example Industries

- Power industry

- Steel industry

- Chemical industry

- Wood board production

Features

- Process temperature: 0 – 1350°C

- Real time sensing: response time below 0.2 second

- High selectivity: automatic compensation for interference effect from other constituents in the gas sample

- High sensitivity: detection limits down to ppb range

- In-situ monitoring: direct in the process, no sample preparation

- Maintenance free: equipped with a self-calibrating feature, no field calibration necessary

- Robustness: IP66 enclosure, suitable for outdoor and indoor installations and harsh environments

- Insensitive to dust and smoke in the measured process: up to 50 g/m3

- ATEX version available

Operating principle

GasEye Extractive is a laser spectrometer that uses single line molecular absorption spectroscopy. A semiconductor laser emits a beam of infrared light which passes through the process and impinges the detector on the receiver side. When the target gas is present the light intensity changes and this can be used to determine the concentration of the measured specimen. The wavelength of the radiation emitted by the laser is chosen to match the specific absorption line wavelength of the gas. The laser continuously scans this single absorption line with a very high spectral resolution. The measurement is free of cross-interferences since the laser light is absorbed very selectively by only one specific line in the scanned spectral range.

INFLUENCES ON THE MEASUREMENT

Temperature

The influence of temperature on the measured absorption line is compensated by internal algorithms. The process gas temperature must be provided as a signal into the instrument. The temperature measurement is used to apply a correction of the temperature on the observed line strength. Temperature compensation is obligatory and without it the concentration output is erroneous.

Pressure

The influence of pressure on the measured absorption line is compensated by internal algorithms. The process gas pressure must be provided as a signal into the instrument. For known pressure values, the GasEye Cross Duct spectrometer adapts the line shape. Additionally, an external pressure signal can be fed to the analyzer to provide complete mathematical compensation of the pressure influence including the density effect (depending on a specific application and target gas).

Interferences

The GasEye Cross Duct can measure the desired gas components very selectively. It may happen that the absorption line of the measured gas is influenced by the presence of other gases. This influence is compensated by the full shape of the detected signal curve analysis and applying algorithms that correct the discrepancies accordingly.

Cross Duct Versions

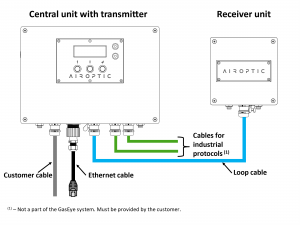

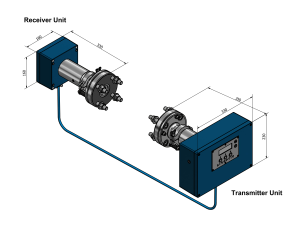

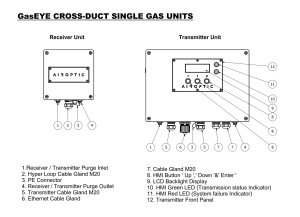

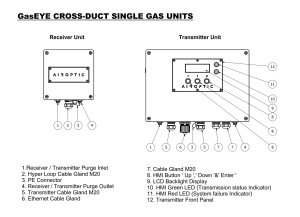

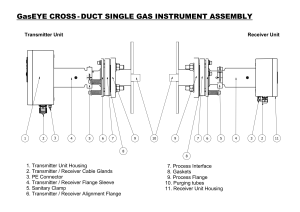

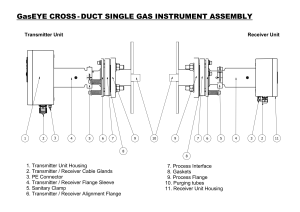

| Dimensions: | width x height: 330 mm x 230 mm, length: 350 mm |

| Weight: | 15 kg |

| Equipment: | display with status indicators, power indicator, 4 cable glands, Ethernet socket, purging fittings |

| Dimensions: | width x height: 160 mm x 160 mm, length: 330 mm |

| Weight: | 13 kg |

| Equipment: | 1 cable gland, purging fittings |

| Degree of protection: | In accordance with IP66 |

| Process windows: | Leak tested and certified in accordance with EN1779:1999 norm. |

|

|

|

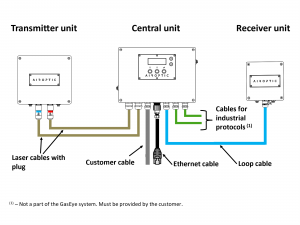

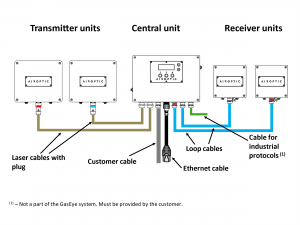

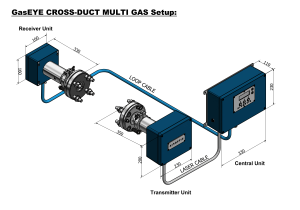

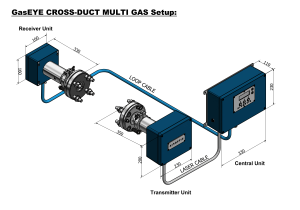

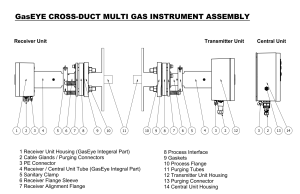

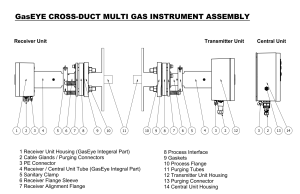

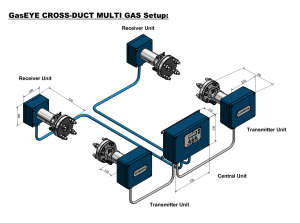

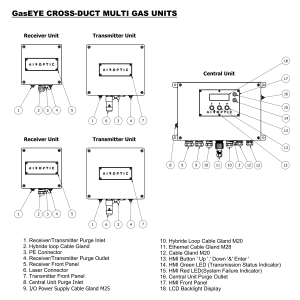

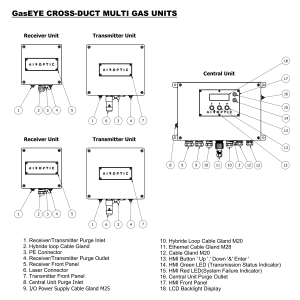

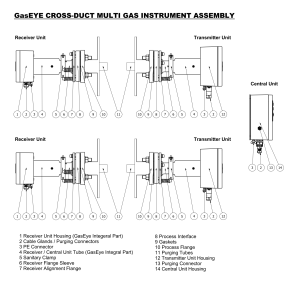

The GasEye Cross Duct MG (Multi Gauge) analyzer consists of a pair of cross-duct sensors – a transmitter and a receiver unit as well as a central unit. The transmitter unit emits laser radiation directly through the process containing the constituents of interest. The receiver unit collects the radiation on the other side of the process duct. The central unit, located close to the transmitter unit (< 2 meters) contains analyzer electronics, MMI and I/O. The receiver unit is connected to the central unit by means of a hybrid loop cable (included) and the transmitter unit is connected to the central unit by one or two electrical cables (included).

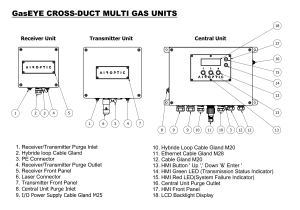

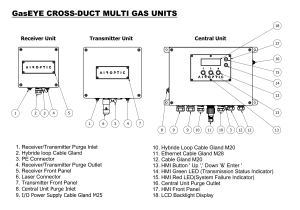

| Dimensions: | width x height: 230 mm x 200 mm, length: 350 mm |

| Weight: | 15 kg |

| Equipment: | 2 x laser sockets, purging fittings |

| Dimensions: | width x height: 160 mm x 160 mm, length: 330 mm |

| Weight: | 13 kg |

| Equipment: | 1 cable gland, purging fittings |

| Dimensions: | width x height: 330 mm x 230 mm, length: 110 mm |

| Weight: | 6 kg |

| Equipment: | display with status indicators, 6 cable glands, Ethernet socket, purging fittings |

| Degree of protection: | In accordance with IP66 |

| Process windows: | Leak tested and certified in accordance with EN1779:1999 norm. |

|

|

|

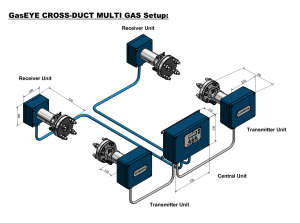

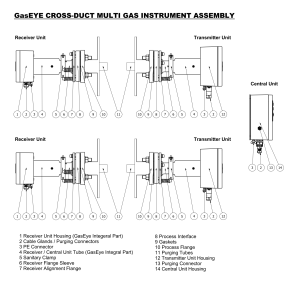

The GasEye Cross Duct MG MP (Multi Gauge Multi-Point) analyzer consists of two pairs of cross-duct sensors – a transmitter and a receiver unit and one central unit. The transmitter unit emits laser radiation directly through the process containing the constituents of interest. The receiver unit collects the radiation on the other side of the process duct. The central unit, located close to transmitter units (< 2 meters) contains analyzer electronics, MMI, and I/O. Each receiver unit is connected to the central unit by means of a hybrid loop cable (included) and each transmitter unit is connected to the central unit by one electrical cable (included).

| Dimensions: | width x height: 230 mm x 200 mm, length: 350 mm |

| Weight: | 15 kg (each) |

| Dimensions: | width x height: 160 mm x 160 mm, length: 330 mm |

| Weight: | 13 kg (each) |

| Dimensions: | width x height: 330 mm x 230 mm, length: 110 mm |

| Weight: | 6 kg |

| Degree of protection: | In accordance with IP66 |

| Process windows: | Leak tested and certified in accordance with EN1779:1999 norm. |

|

|

|

Safety

| RoHS Directive 2011/65/EU | |

| Low Voltage Directive (LVD) 2014/35/EU | PN-EN 60825-1:2014-11 – Safety of laser products – Part 1: Equipment classification and requirements |

| PN-EN 61010-1:2011 – Safety requirements for electrical equipment for measurement, control and laboratory use – Part 1: General requirements | |

| Electromagnetic Compatibility Directive (EMC) 2014/30/UE | Emission: |

| EN 55016-2-1:2014+A1:2017 – Measurements of conducted disturbances emission | |

| EN 55016-2-3:2017+A1:2019 – Measurements of radiated disturbances emission | |

| Immunity: | |

| EN 61000-4-2:2009 – Electrostatic discharge immunity | |

| EN 61000-4-3:2006 + A1:2008 + A2:2010 – Radiated, electromagnetic field immunity | |

| EN 61000-4-4:2012 – Electrical fast transient / burst immunity | |

| EN 61000-4-5:2014 + A1:2017 – Surge immunity | |

| EN 61000-4-6:2014 – Immunity to conducted disturbances | |

| EN 61000-4-29:2000 – Immunity to voltage dips, short interruptions and voltage variations | |

| ATEX Directive 2014/34/EU | EN IEC 60079-0:2018 – Explosive atmospheres – Part 0: Equipment – General requirements |

| EN 60079-2:2014 – Explosive atmospheres – Part 2: Equipment protection by pressurized enclosure “p” | |

| EN 60079-11:2012 – Explosive atmospheres – Part 11: Equipment protection by intrinsic safety “i” | |

| EN 60079-26:2015 – Explosive atmospheres – Part 26: Equipment with Equipment Protection Level (EPL) Ga | |

| EN 60079-28:2015 – Explosive atmospheres – Part 28: Protection of equipment and transmission systems using optical radiation | |

|

Explosion protection (standard version):

|

|

| Explosion protection – ATEX Zone 1/21 (optional version): GasEye Cross Duct Ex1:

GasEye Cross Duct Ex1 IS:

GasEye Cross Duct Ex1 ET and GasEye Cross Duct Ex1 ET IS:

Certificate No. KDB 20ATEX0003X EN |

|

|

Explosion protection – IECEx Zone 2/22 (optional version):

|