Water Vapor (H2O) ANALYZER

Extractive Single Gauge

GasEye Extractive H2O

Water Vapor ANALYZER

GasEye H2O is a high performance hydrogen sulfide analyzer. Suitable for safety applications and process control. 24/7 continuous operation. No sample preparation. No zero drift. No field calibration. Low cost of ownership.

Features

- H2O ranges: 0 – 5 ppmv / 0 – 100 ppmv

- Process temperature: 0 – 100°C

- Real time sensing: response time below 0.1 second

- High selectivity: automatic compensation for interference effect from other constituents in the gas sample

- High sensitivity: detection limit below 0.2 ppmv

- Maintenance free: equipped with a self-calibrating feature, no field calibration necessary

- Robustness: IP66 enclosure, suitable for outdoor and indoor installations and harsh environments

- ATEX version available

Example Applications

- Process control

- Safety monitoring

- Gas quality measurement

Example Industries

- Petrochemical industry

- Chemical industry

- Power industry

- Steel industry

Application type

| Process gas temperature: | 0ºC to 200ºC (depends on application) |

| Process gas pressure: | 0.05 – 0.35 barG |

| Warm-up time: | approx. 20 minutes |

| Minimum response time (T90): | 100 milliseconds |

| Ambient temperature: | -30ºC to +60ºC |

| Ambient pressure: | 800 – 1200 hPa |

| Ambient humidity: | RH < 99%, non-condensing |

| Purging gas: | instrument air or N2 |

| Sensor purge flow rates: | 0.2 – 7 l/min |

Technical specification

| Outputs: | 4 x analog output 4 – 20 mA (gas concentration, process transmission, 2 x AUX) – easy user selection via DIP switch between active/passive mode |

| 8 x digital output (NAMUR) | |

| Inputs: | 4 x analog input 4 – 20 mA (process temperature and pressure) – easy user selection via DIP switch between active/passive mode |

| 1 x RTD (PT100/PT1000) - easy user selection via DIP switch between PT100/PT1000 and 2-/3-/4-wires | |

| 8 x digital input | |

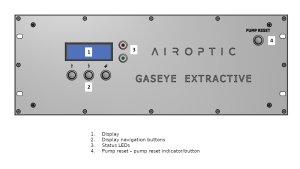

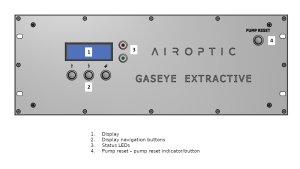

| Local User Interface: | Human Machine Interface (HMI) - LCD backlight display located on the transmitter housing lid |

| Ethernet port: a) WebServer – system configuration and data acquisition via web browser, b) Windows based program – GasEye logger for real-time data acquisition, c) remote service and diagnostics |

|

| Optional: | Modbus (TCP/IP), Modbus RTU, Profinet, Profibus |

| Power input: | 230 VAC nominal (100 – 240 VAC) |

| Power consumption: | < 300VA (< 400VA if ATEX) |

| Automatic gain control (AGC): | AGC ensures correct gas measurement even at high dust loads resulting in loss of optical transmission down to 0.5%. AGC operates fully automatic with no need for manual adjustment of the signal gain under any process conditions. |

| Self-calibration features: | Internal reference gas compartment is used for closed loop control of the zero and span drift |

| Download a file: | |

| GasEYE system elements: | preview |

| Active analog input: | preview |

| Active analog output: | preview |

| Passive analog input: | preview |

| Passive analog output: | preview |

| Isolated Digital Input: | preview |

| Isolated Digital Output: | preview |

| PT100/PT1000 2-wire: | preview |

| PT100/PT1000 3-wire: | preview |

| PT100/PT1000 4-wire: | preview |

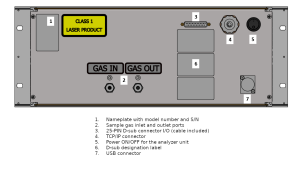

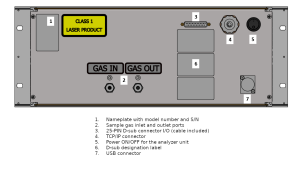

GasEye Extractive 19" RACK analyzer is assembled in a standard 19-inch rack 4U version.

It exists in several various configurations from single gas to multi gas applications.

|

|

|

| Dimensions: | width x height: 482 mm x 177 mm length: 650 mm |

| Weight: | 35 kg (for the model with multipass cell, vacuum pump, and safety valves) |

| Gas connection: | 6 mm tubing |

| Housing: | aluminum |

| Internal process cell: | stainless steel 316 |

| Cell window: | sapphire |

| Low Voltage Directive (LVD) 2014/35/EU | PN-EN 60825-1:2014-11 – Safety of laser products – Part 1: Equipment classification and requirements | |

| PN-EN 61010-1:2011 – Safety requirements for electrical equipment for measurement, control and laboratory use – Part 1: General requirements | ||

| RoHS Directive 2011/65/EU | ||

GasEye Extractive Wall Mounted type analyzer exists in general purpose and hazardous area configuration (version Ex1). It exists in several various configurations from single gas to multi gas applications. The system is IP66 rated with ambient temperature ranges from -30ºC to +60ºC and can be mounted outside without a need for a container.

GasEye Extractive Ex1 provides Ex p (purge and pressurization) type of explosion protection. Ex p pressurized equipment is the technique of guarding against ingress of the external atmosphere into an enclosure by maintaining a protective gas therein at a pressure above that of the external atmosphere. The overpressure is maintained either with or without a continuous flow of the protective gas.

|

|

|

| Dimensions: |

width x height: 460 mm x 230 mm |

| Weight: | 60 kg |

| Gas connection: | connector 6 mm Swagelok |

| Housing: | SS 1.4301 (AISI 304) |

| Internal process cell: | SS 1.4404 (AISI 316L) |

| Cell window: | sapphire |

| Low Voltage Directive (LVD) 2014/35/EU | PN-EN 60825-1:2014-11 – Safety of laser products – Part 1: Equipment classification and requirements | ||||||||||||||||||||||||

| PN-EN 61010-1:2011 – Safety requirements for electrical equipment for measurement, control and laboratory use – Part 1: General requirements | |||||||||||||||||||||||||

| RoHS Directive 2011/65/EU | |||||||||||||||||||||||||

| ATEX Directive 2014/34/EU | EN IEC 60079-0:2018 - Explosive atmospheres - Part 0: Equipment - General requirements | ||||||||||||||||||||||||

| EN 60079-2:2014 - Explosive atmospheres - Part 2: Equipment protection by pressurized enclosure "p" | |||||||||||||||||||||||||

| EN 60079-26:2015 - Explosive atmospheres - Part 26: Equipment with Equipment Protection Level (EPL) Ga | |||||||||||||||||||||||||

| EN 60079-28:2015 - Explosive atmospheres - Part 28: Protection of equipment and transmission systems using optical radiation | |||||||||||||||||||||||||

|

Explosion protection (standard version):

|

|||||||||||||||||||||||||

|

Explosion protection - ATEX Zone 1/21 (optional version): GasEye Extractive Ex1:

GasEye Extractive Ex1 ET:

*/** temperature class depends on the medium temperature according to:

Certificate No. KDB 20ATEX0056X EN |

|||||||||||||||||||||||||